Custom Insulation Board

Custom insulation board with you in mind! Insulation Supply will happily custom cut rigid insulation board to your specifications and deliver to your company or job-site. In addition to offering virtually any width, length and thickness, we also have a variety of edge types such as tongue and groove, shiplap, furlap and channel that will meet the demands of your project. Our conveniently located, state of the art facility in Northeast Ohio is known for its quick turnaround times. We offer both delivery and store pickup options. Our knowledgeable staff can help you with any questions as we encourage you to call or use the contact form below.

Custom Length and Width

Our hot wire cutting process allows for a wide variety of lengths and widths at any quantity. Both length and width measurements start at 1″ and increase by 1/8″ increments. Max width tops out at 4′ while max length can be up to 9′ for some rigid insulation varieties.

Custom Thickness

We use two methods for changing the thickness of our custom foam insulation. Planing is a process of shaving down the foam board rather than cutting it, leaving a smooth finish. We can also cut the thickness with a bandsaw, which splits the insulation board in half. Boards cut with the bandsaw method are left with a more rough finish on one side. Both methods will leave one side of the foam board insulation unfinished.

Insulation F-Types

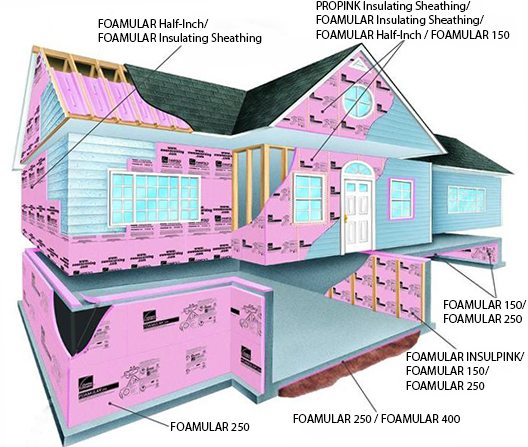

Several types of foam board insulation are available. Each variety corresponds to its own density and pressure rating. All FOAMULAR® XPS products are R-5 per inch of thickness except High-R CW Plus that is R-10 at 1-3/4″, and R-12 at 2 1/8 ” thick.

FOAMULAR 150: 15 PSI & 250: 25 PSI

All-purpose foam panel insulation for masonry and other applications. Owens Corning™ FOAMULAR® 150 & 250 extruded polystyrene insulation is ideal for wall furring, perimeter/foundation, cavity wall, crawlspace, pre-cast concrete, under slab, sheathing and other applications (Not approved for roofing). Owens Corning’s patented Hydrovac® process technology makes the unique closed-cell structure of FOAMULAR® extruded polystyrene insulation highly resistant to moisture, retaining its long term R-value year after year – even following prolonged exposure to water leakage, humidity, condensation, groundwater and freeze/thaw cycling.

FOAMULAR 400: 40 PSI, 600: 60 PSI & 1000: 100 PSI

Owens Corning™ FOAMULAR® 400, 600 and 1000 are high strength extruded polystyrene (XPS) insulation products designed for use in engineered applications requiring additional load-bearing capability such as under slab, concrete floors, foundations, roadways and rail beds, plaza and parking decks and cold storage installations.

FOAMULAR® High-R CW Plus: 25 PSI

The main advantage of High-R CW Plus insulation over other extruded polystyrene boards is its higher R-Value per inch. An R-Value of 10 can be achieved with just a 1¾” thick board. Standard extruded polystyrene requires a thickness of 2” to achieve an R-10. This gives the designer the opportunity to increase the air gap (thereby decreasing mortar bridging and improving the cavity performance) while maintaining the same thermal performance as a standard 2” extruded polystyrene board. Additionally, the designer can also choose to increase the thermal performance of the wall assembly by choosing High-R CW Plus insulation with a thickness of 2⅛”. This provides an R-value of 12 with only a slight increase in board thickness.

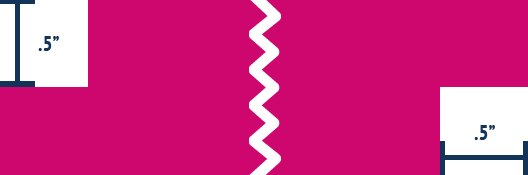

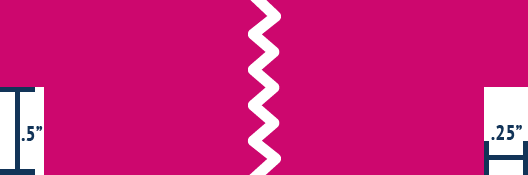

Edge Type Profiles

All insulation boards start with standard, squared edges which work well as a most any format. At Insulation Supply, we have a great variety of custom edge styles available for a multitude of applications.

Tongue & Groove Edge

Tongue & groove edges allow insulation boards to interlock, much like shiplap edging. This type of edge covers the two long sides of each board and allows for greater thermal performance by creating a virtually seamless transition between them.

Ship-Lap Edge

Shiplap edge insulation is cut so that the boards interlock on all four sides allowing for superior thermal performance. The advantage of interlocking insulation boards is that it eliminates the small gaps that can be found between squared edge boards. This edging is typically used on exterior walls, but can be useful in many other applications as well.

Furlap Edge

Used to insulate the interior of basement or other concrete or block walls, furlap edge insulation accommodates a nailing strip which is used to attach the foam boards to the wall and provide framing to attach the finish surface such as drywall.

Channel Edge

Channel edge cuts run around all four sides of the rigid insulation board and are used mainly for drainage. Use this cut either alone or in conjunction with rib channels for maximum flow. This type of edging is used mainly for roofing applications over top of a membrane.

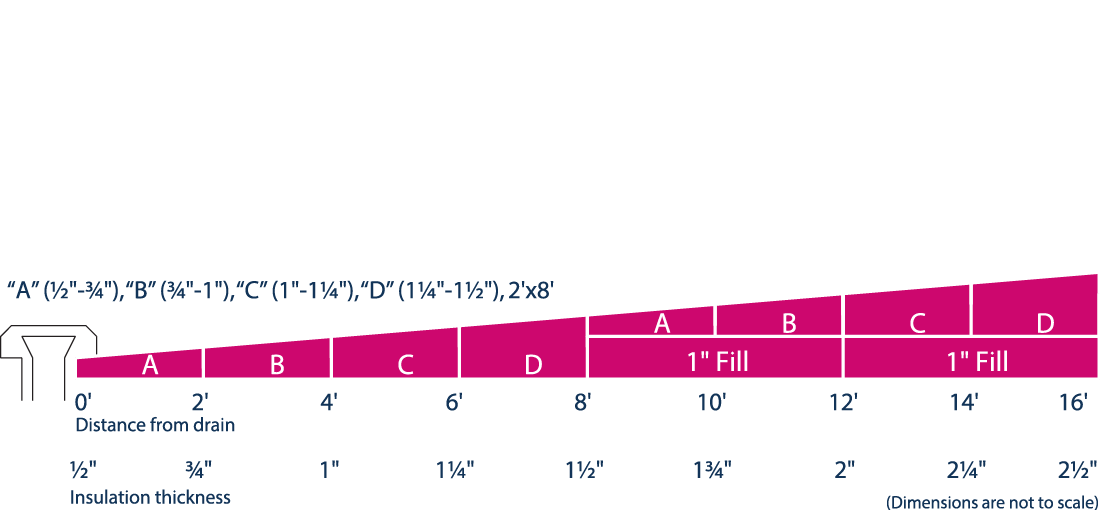

Tapers / Slopes

Slopes and tapers can be planed or band sawed depending on your needs. Tapered roof insulation provides a sustainable roofing solution, helping to prevent ponding and damaging ice build up in winter, while in summer resisting the growth of fungus and vegetation. Tapered insulation is installed on top of a vapor membrane to create a low sloped roof for optimal flow of water into a drain or gutter.

- Slopes of any letter at any degree based on your individual need

- Planing leaves no scrap

- Band sawing allows for two pieces from one sheet, but leaves a rough finish

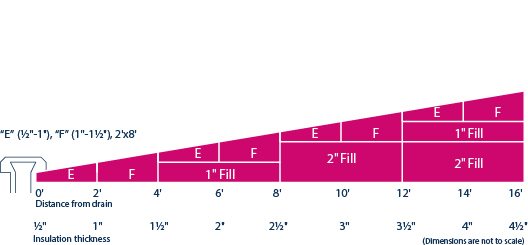

Typical Tapered Roofing Section 1⁄8″ per foot slope

Typical Tapered Roofing Section 1⁄4″ per foot slope

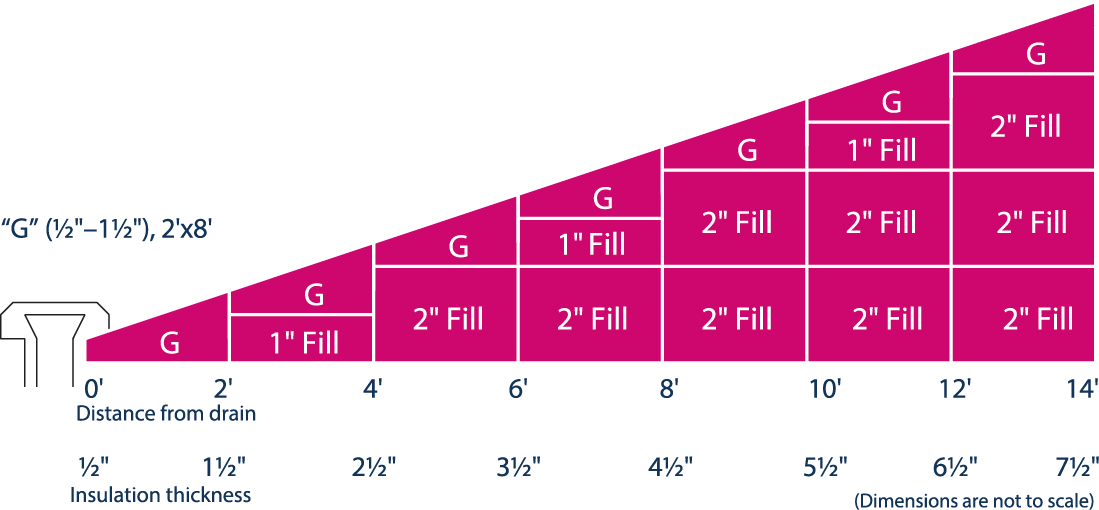

Typical Tapered Roofing Section 1⁄2″ per foot slope

Channel Board

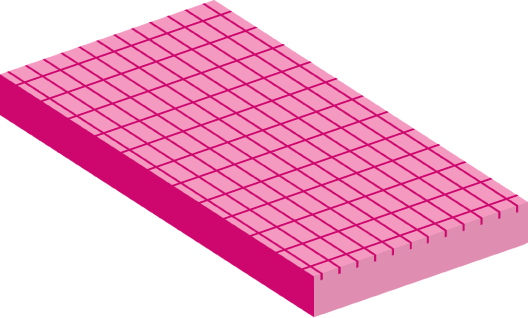

At Insulation Supply we custom cut your rigid insulation to basically any configuration such as channel board. These boards can be used in exterior foundation walls to help protect membranes while allowing water to drain into the ground.

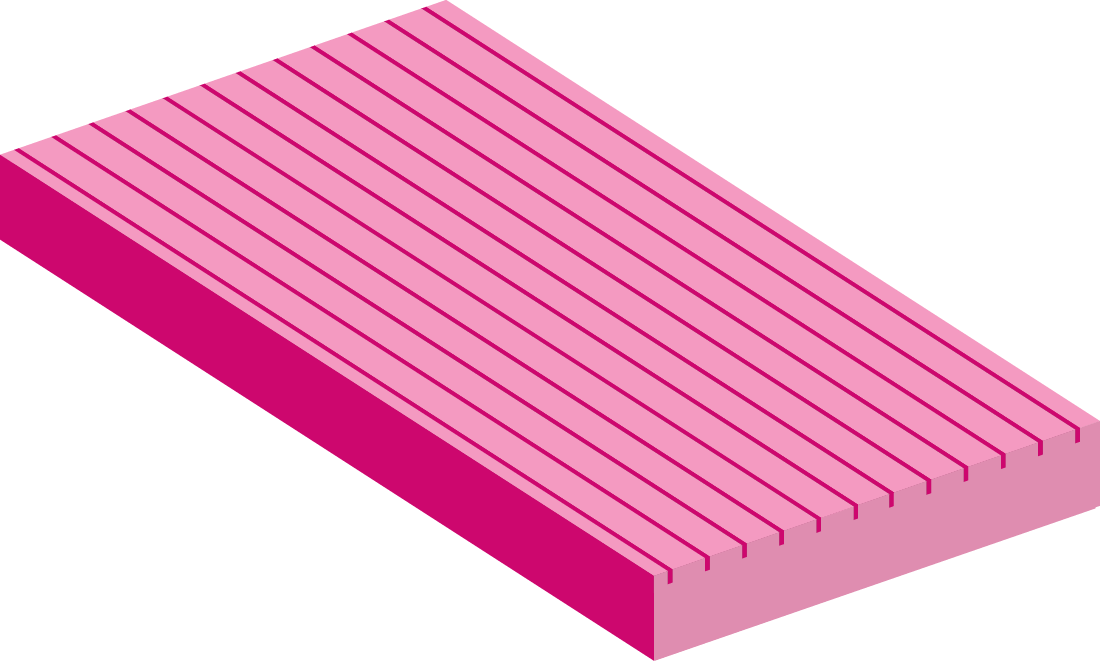

Ribbed Board

These precision-cut channels drain water from vertical foundation walls while providing a continuous envelope of insulation. The channel design prevents soil from clogging channels assuring long-term performance.

Channel Board

Custom cut boards can provide superior drainage capacity & protection for ground water concerns. Used in exterior foundation walls above and below grade and includes durable filtration fabric than prevents soil from clogging channels.

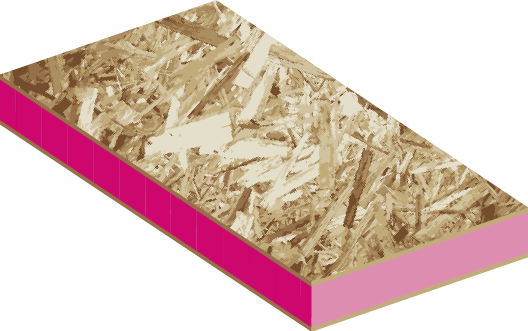

SIP Panel & Custom Laminated Boards

In addition to custom size rigid insulation, Insulation Supply can assemble both SIP (Structural Insulated Panels) and laminated boards using a wide variety of materials. We used advanced adhesives to attach the layers to the rigid insulation boards and can fabricate virtually any configuration for your project or industry.

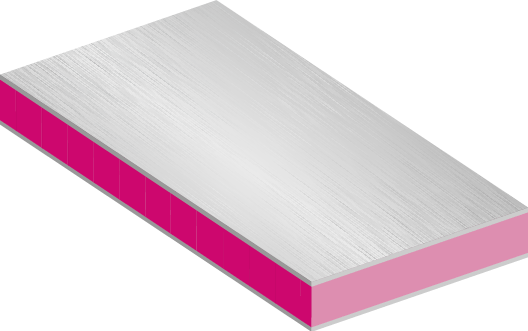

SIP Panels

SIP panels are rigid insulation boards sandwiched between 2 layers of a particular substrate. They are an efficient and economical prefabricated solution for numerous construction applications.

Laminated Board

Laminated panels are covered with an often flexible material such as foil or cloth. Insulation Supply can custom cover your order to spec.

Precision Planing Services

Our state of the art equipment can custom cut your order to within .0005 of an inch for those projects that require absolute precision. Contact us today to discuss your project with one of our experts.

Contact Information & Hours of Operation

Address:

281 Southwest Avenue

Tallmadge, OH 44278

Hours of Operation:

Monday: 7:30am – 4:00pm

Tuesday: 7:30am – 4:00pm

Wednesday: 7:30am – 4:00pm

Thursday: 7:30am – 4:00pm

Friday: 7:30am – 4:00pm

Saturday: Closed

Sunday: Closed

Phone:

1 (844) 446-7858